EndoTherm™ and EndoCool™ are award-winning, energy-saving additives that can be installed into ANY hydronic heating or chilled water system.

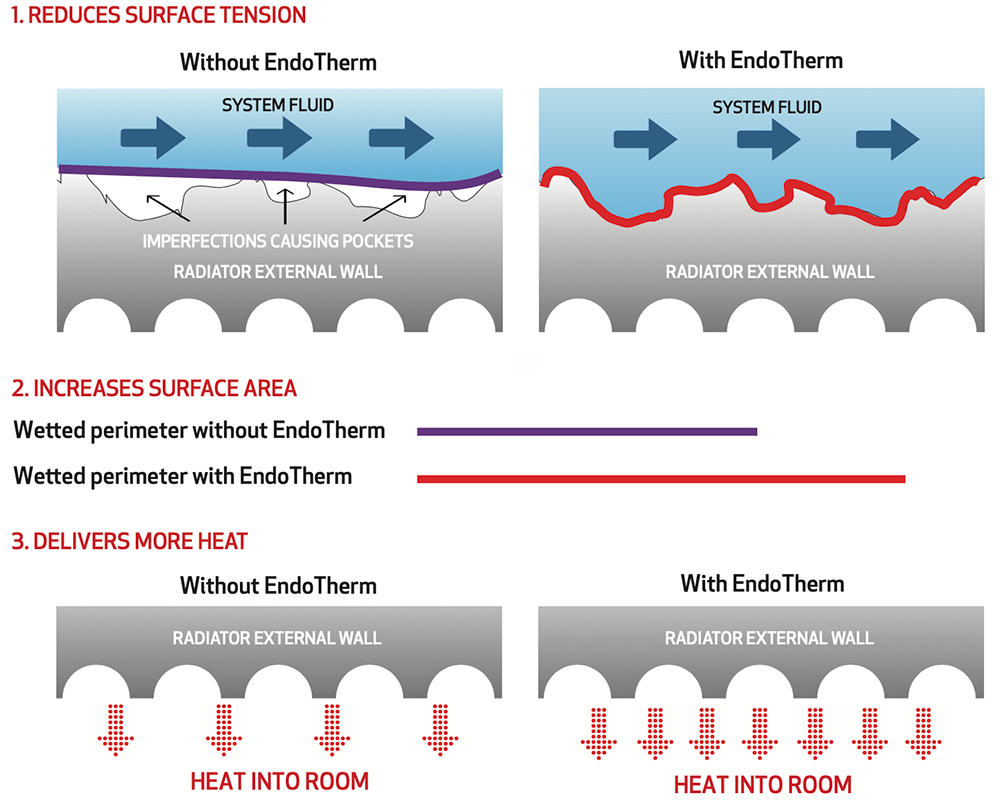

Water is used in the majority of commercial heating and cooling systems in North America. It is readily available and inexpensive. While water contains some good heat transfer qualities, its high surface tension reduces thermal contact, therefore detracting from its efficiency as a heat transfer fluid.

EndoTherm and EndoCool reduces the surface tension of water, which allows for improved heat transfer efficiency. Ultimately, this increases the performance hydronic heating and chilled water systems.

EndoTherm has been independently proven to use up to 15% less fuel to maintain the same temperature levels than water alone.

EndoTherm and EndoCool have been successfully installed into tens of thousands of commercial and domestic locations worldwide.

When dosed into a hydronic heating system at a 1% concentration, EndoTherm’s unique formula reduces the surface tension of water by over 60%.

Maintains heat for longer, reducing the demand for heat.

Increased heat loss reduces water return temperatures. This allows boilers to condensate more and recover more latent heat. This also reduces flue gas losses.

System water heats up faster due to improvement in nucleate boiling.

Increases cycle length, therefore reducing the number of boiler cycles and energy consumption.

All product claims have been tested and proven by respected, independent authorities.

Enertek International is a privately owned independent R&D company who work on projects on behalf of major multinational corporations, leading private companies, trade associations, and government departments.

“Direct comparison tests with and without EndoTherm in the system water indicate that the gas consumption of the boiler in the heating system can be reduced by up to 15%. This empirical evidence indicates that the addition of EndoTherm can significantly reduce gas consumption and therefore CO2 emissions.”

The University of the West of Scotland investigated the impact of EndoTherm as an energy saving technology.

THERMAL TRANSFER

The rate of heating and cooling was investigated using a test cell and digital thermometer. EndoTherm achieved a 19.2% improvement in heating during the experiment. The test also showed that EndoTherm liberated this thermal energy much quicker through an improvement in heat transfer.

There is negligible difference in bacterial growth (cfu/ml) between cycles with/without EndoTherm when cycled up to 50°C. Cycling up to 65°C eliminates the majority of bacteria.

Worcester, Bosch tested for any detrimental effects that EndoTherm may have on their boilers. As a result they confirmed that EndoTherm will not adversely affect any components of a Worcester boiler, or affect the associated warranties.

The BuildCert approved laboratory, Midland Corrosion ran corrosion tests on EndoTherm with a leading brand inhibitor using standard hard and soft water over a 14 day period. The combined solution was well within BuildCert Limits for a number of materials including aluminium, steel and copper.

The dosage of EndoTherm had no effect on the concentration or freeze point of the prepared inhibited propylene glycol sample after 303 days at room temp. There was also no effect when the sample temp was maintained at -16.0°C/3°F for 48 hours. The carbon steel and copper coupons were in perfect condition, with no visual signs of corrosive attack.

EndoTherm has been installed into a large number of commercial properties. The actual savings obtained by users of EndoTherm, during the study period, have been recorded.. Each installation is surveyed to identify the required volume of EndoTherm and the suitability of a site to run a study. The suitability requires repeatable, accurate meter readings and a constant base load with no significant changes in use/technology over the comparison period.

Where appropriate, the field tests follow the IPMVP protocols using regression analysis to identify historical trends in the building usage. This data can be compared with post-installation consumption to determine savings. Where past data is not sufficient, the usage is directly compared with a suitable historical term (usually year on year). All studies are compensated using heating degree days from a nearby weather station.

The main campus of the University of British Columbia (UBC) is connected to a large district energy system powered by three 15MW boilers to meet the heat demand of the main UBC campus. The wider network includes over 11km of insulated pipes and over 100 heat transfer stations.

Where appropriate, the field tests follow the IPMVP protocols using regression analysis to identify historical trends in the building usage. This data can be compared with post-installation consumption to determine savings. Where past data is not sufficient, the usage is directly compared with a suitable historical term (usually year on year). All studies are compensated using heating degree days from a nearby weather station.

Improving the performance of the secondary network (building side) within a district energy system can greatly improve the efficiency of the whole district system. One of these secondary systems provides heat to UBC Horticulture, a building which historically has struggled to reach desired set-points.

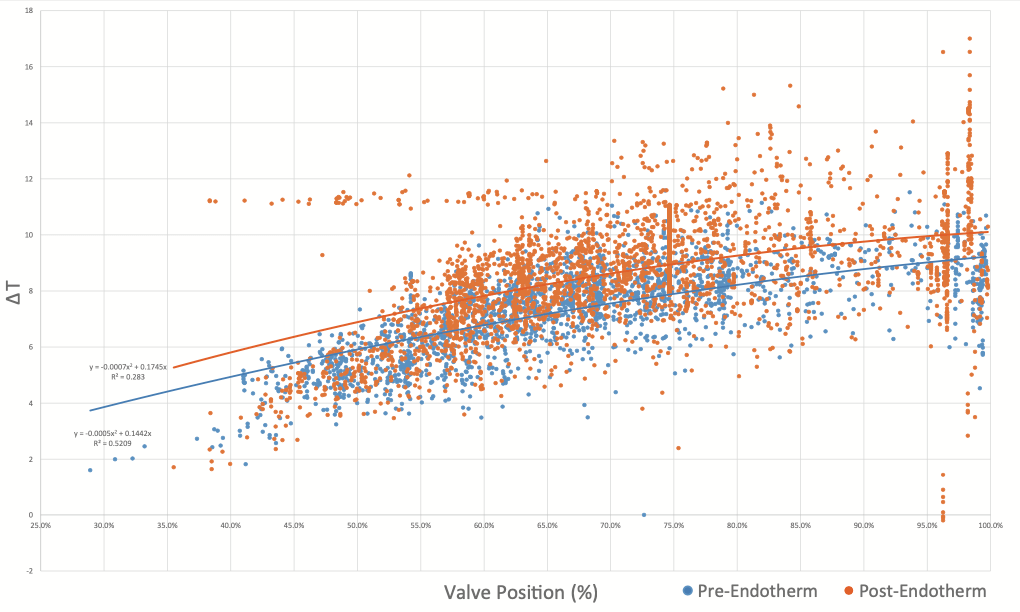

EndoTherm was installed into UBC horticulture to improve the system ΔT’s through improved heat

transfer efficiency.

The data, taken with 15-minute intervals over several months shows a clear increase in ΔT at different valve positions after EndoTherm has been installed. The average improvement in ΔT has been recorded at 1.02°C, a 15.23% improvement. UBC’s energy engineer also noted the building was able to satisfy the thermostatically controlled temperature even during extreme cold periods.

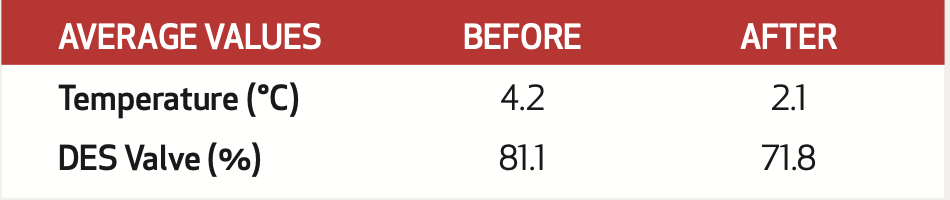

The recorded Variable Valve Position of the secondary pump was, on average, lower after EndoTherm was installed when compensated with the outside temperature. This is a notable improvement in the efficiency of the secondary system. The DES Valve was lower post EndoTherm install despite the average temperature being more than 2°C colder

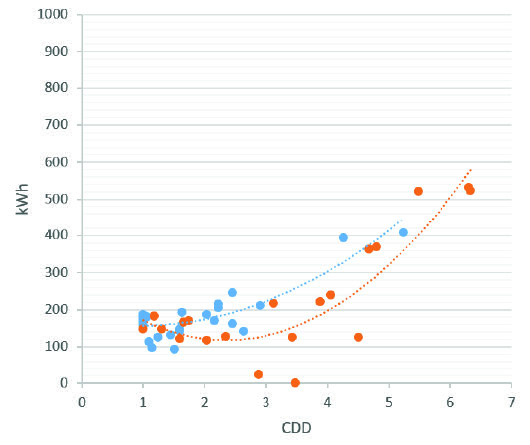

The world’s first EndoCool trial was conducted by an internationally renowned construction and facilities management company on sites owned by a national utility provider.

The trial was conducted on a three storey office building with Fan Coil Units (FCU) for comfort cooling during operational hours (8am to 6pm). The site also has a small server room which is constantly cooled.

The site is monitored with real-time data using a Panoramic Power platform and lined to Pan 14 sensors. These circuits measure the current within the chiller and can identify site specific results on energy consumption and cost based on 13.87 cents/kWh of electricity.

With the continuous information available there are a number of ways in which the data can be compared. The Panoramic Platform automatically collates the average temperatures and cooling degree days (CDD) from the nearby weather station which can be used to compensate for different external temperatures.

The International Performance Measurement and Verification Protocol (IPMVP) was designed by the US Department of Energy as a ‘best practice’ methodology for quantifying the results of energy efficiency technologies. The protocol uses historical data to provide a baseline of energy which can be compared with results achieved once the energy saving technology has been installed.

The historic usage between the 1st June 2017 to the 3rd July 2017 was plotted against Cooling Degree Days at 15.5°C.

Note: the IPMVP protocol typically uses an 18.5°C. Due to the milder UK climate with average temperatures below 18.5°C it was not deemed suitable for this application and 15.5°C was utilised.

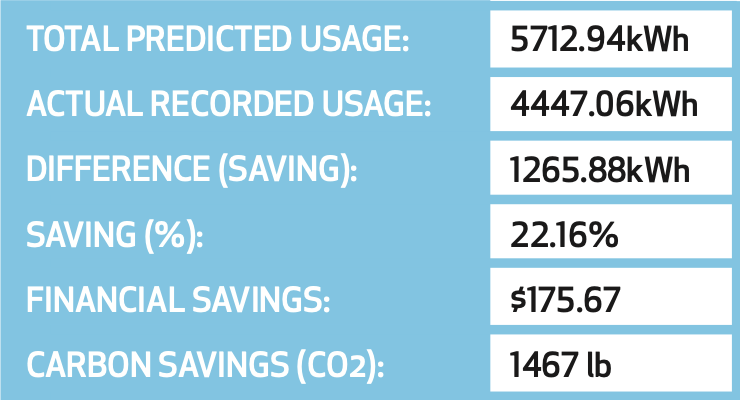

The trend line calculated from the before period can be utilised to predict what the consumption would have been each day if EndoCool had not been installed. The difference between this prediction and the actual usage is the saving per day. The cumulative saving of each day is known as CUSUM analysis.

For more information about EndoTherm™ & EndoCool™, send us an email at info@coolbreezeair.com